How Ancient Coins Were Minted: Techniques and Tools

Chosen theme: How Ancient Coins Were Minted: Techniques and Tools. Step into the heat of historic mints to discover how metal, muscle, and meticulous craftsmanship turned raw ore into symbols of power, trust, and everyday trade. Subscribe if you love history forged by hand.

From Furnace to Marketplace: The Birth of Coinage

In Lydia, artisans shaped naturally occurring electrum into standard pieces, testing weight with small scales and stamping symbols to certify value. Comment if you have a favorite early coin type or museum story.

From Furnace to Marketplace: The Birth of Coinage

Mints transformed rulers’ emblems into daily assurance. Each strike declared weight, fineness, and legitimacy. Share how standard markings help you trust objects today, from seals on packages to tamper-evident labels.

From Furnace to Marketplace: The Birth of Coinage

Picture a runner delivering fresh silver to a bustling agora. The clatter of tools fades into the sharper sound of new coins. Would you have traded immediately, or waited to see if the stamp held?

Fire and Metal: Smelting, Alloying, and Annealing

Clay crucibles swallowed ore and charcoal while leather bellows fed the flame. The mint smelled of resin and hot clay. Tell us: which ancient tool fascinates you most, the bellows or the crucible?

Metal flowed into molds, cooled into rods, then was sliced into discs. Each slice’s weight mattered; small errors multiplied quickly. Have you tried cutting metal blanks in a workshop or class?

Shears trimmed ragged edges; files corrected weight to meet standards. Overweight pieces were carefully shaved; underweight pieces were remelted. Share your favorite precision tool and how it changes your craft results.

A rough flan obscured fine details, so surfaces were smoothed and reheated. A ready flan gleamed softly, primed to take the die’s art. Would you prioritize speed or surface perfection as a mint worker?

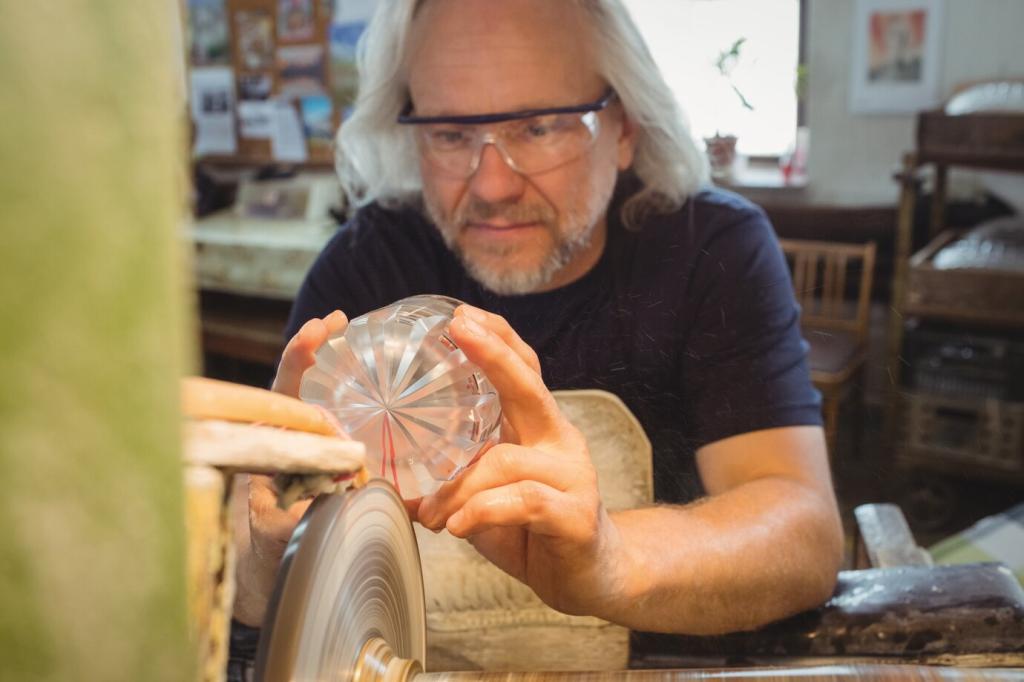

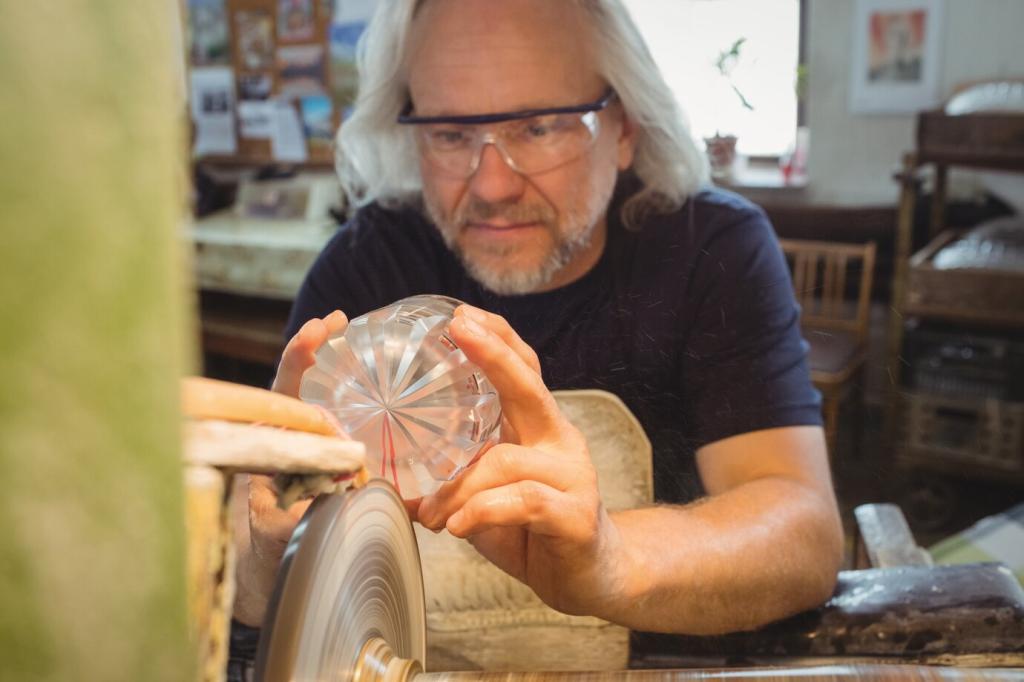

Burin, Punch, and the Engraver’s Hand

Using burins, punches, and scrapers, engravers carved mirrored letters and portraits into dies. One slip altered a ruler’s profile forever. Comment if you have tried hand engraving or letter cutting yourself.

Hardening and Tempering the Die

After engraving, dies were hardened so they could survive thousands of blows. Too hard, and they shattered; too soft, and details blurred. Which failure would you fear more: cracks or mushy strikes?

Design Choices that Survive the Hammer

Engravers planned raised borders and bold lines to resist distortion during impact. Subtle relief, crisp legend spacing, and guide dots made beauty durable. Subscribe for upcoming sketches of reconstructed die layouts.

Anvil Die Below, Punch Die Above

The lower die anchored the design; the upper die carried the counterpart. With tongs and steady hands, a striker delivered a focused blow. How would you design a safer alignment jig for speed?

Off-Center Hits and Double Strikes

Without collars, flans slipped, causing off-center images and accidental doubles. These quirks charm collectors today. Share a photo or story of a mis-struck coin you’ve seen in a museum or book.

Rhythm, Teams, and Throughput

Mints worked in teams: feeder, holder, striker. Rhythmic hammering signaled efficiency and morale. Imagine keeping pace for hours. Would you rotate roles or specialize to maintain quality and speed?

Cast Coinage Traditions: Molds, Sprues, and Coin Trees

Artisans carved characters and rims into paired molds, then added channels for metal flow. When poured, coins formed along branches. Which part of mold-making intrigues you most: carving or vent design?

Cast Coinage Traditions: Molds, Sprues, and Coin Trees

After cooling, workers snapped coins from sprues and filed the gates. The process balanced mass production with careful finishing. Tell us if you’ve seen a coin tree reconstruction or handled replica sprues.

Scales, Weights, and Tolerances

Balances with calibrated weights checked every batch. Slight deviations were acceptable; larger ones demanded remelting. What tolerance would you allow if you ran a mint under wartime pressure and shortages?

Test Cuts and Banker’s Marks

Merchants sometimes cut or punched coins to verify metal quality. Though controversial today, these marks reveal historic skepticism. Have you spotted a banker’s mark on a coin or in a catalog photo?

Die Wear, Re-Engraving, and Replacement

As dies wore, details softened; engravers refreshed lines or introduced new dies. Tracking wear protected standards. Subscribe to receive our upcoming guide to identifying die states in ancient series.

Tools of the Trade: A Mint Worker’s Kit

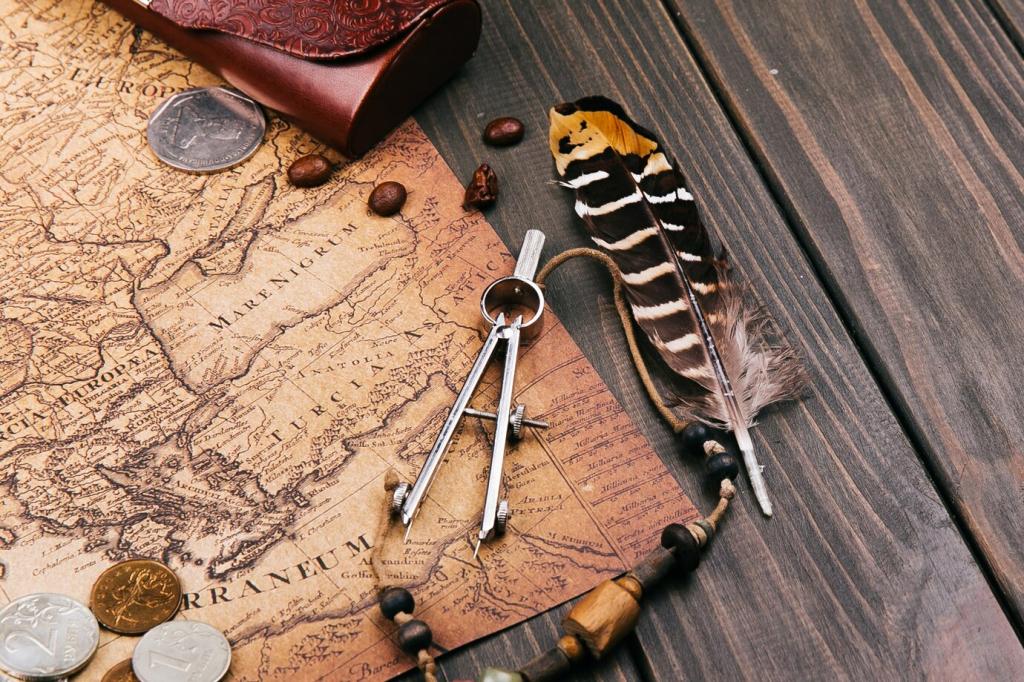

Inventory of an Ancient Mint

Expect furnaces, crucibles, bellows, tongs, shears, files, punches, burins, dies, hammers, scales, molds, and quench buckets. Which tool would you most want to handle during a hands-on workshop tour?

Safety, Workflow, and Skill

Heat-resistant pads, careful tongs work, and predictable paths for hot metal reduced accidents. Workflow discipline mattered as much as strength. Share your best tip for safe crafting or metalworking at home.

The Mint’s Soundscape and Memory

Veterans recalled heat on the face, the hiss of quenches, and the ring of strikes. Those sensations became pride. Subscribe, and tell us which sensory detail anchors your strongest workshop memory.